What Is Rebabbitting?

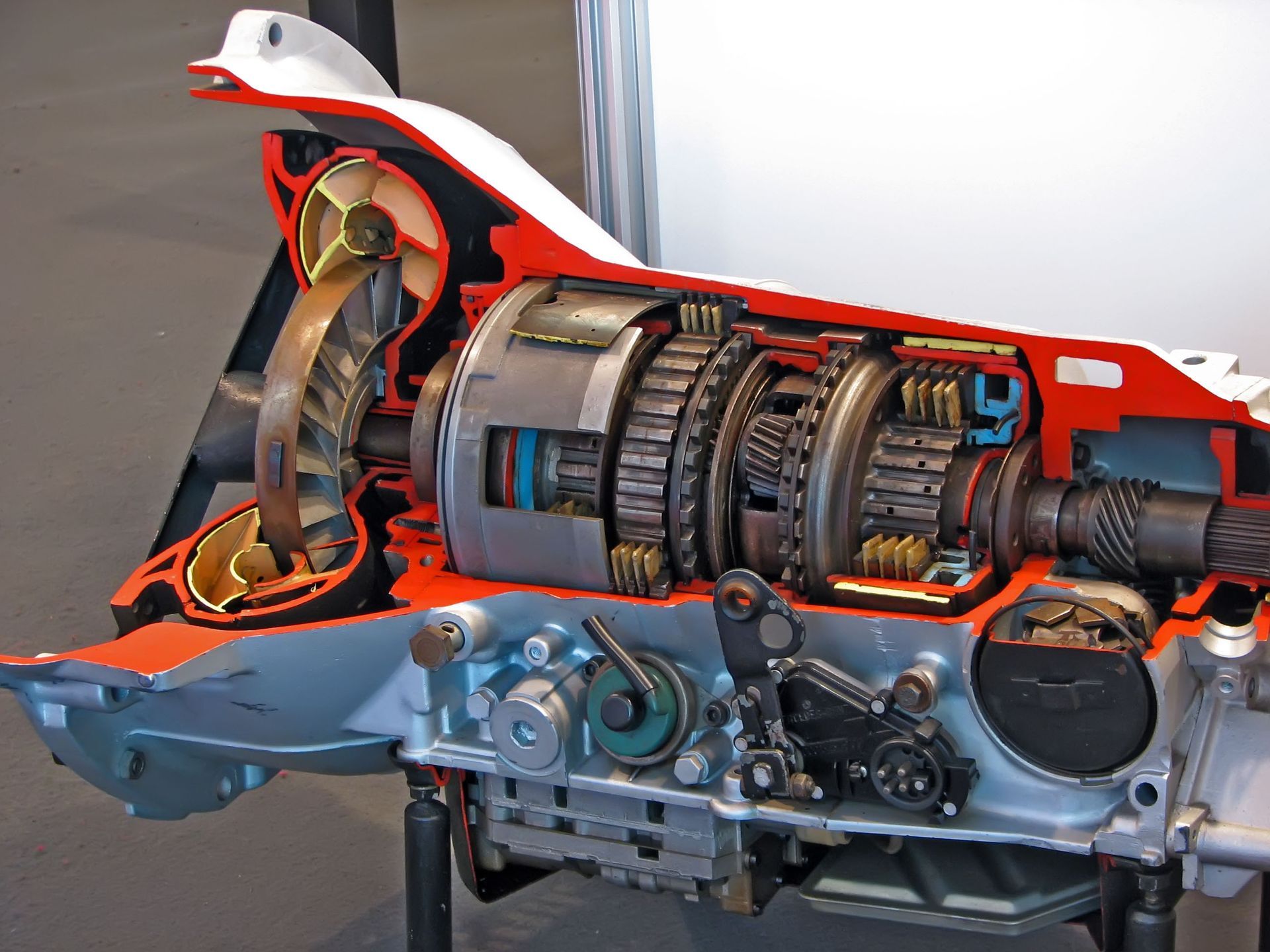

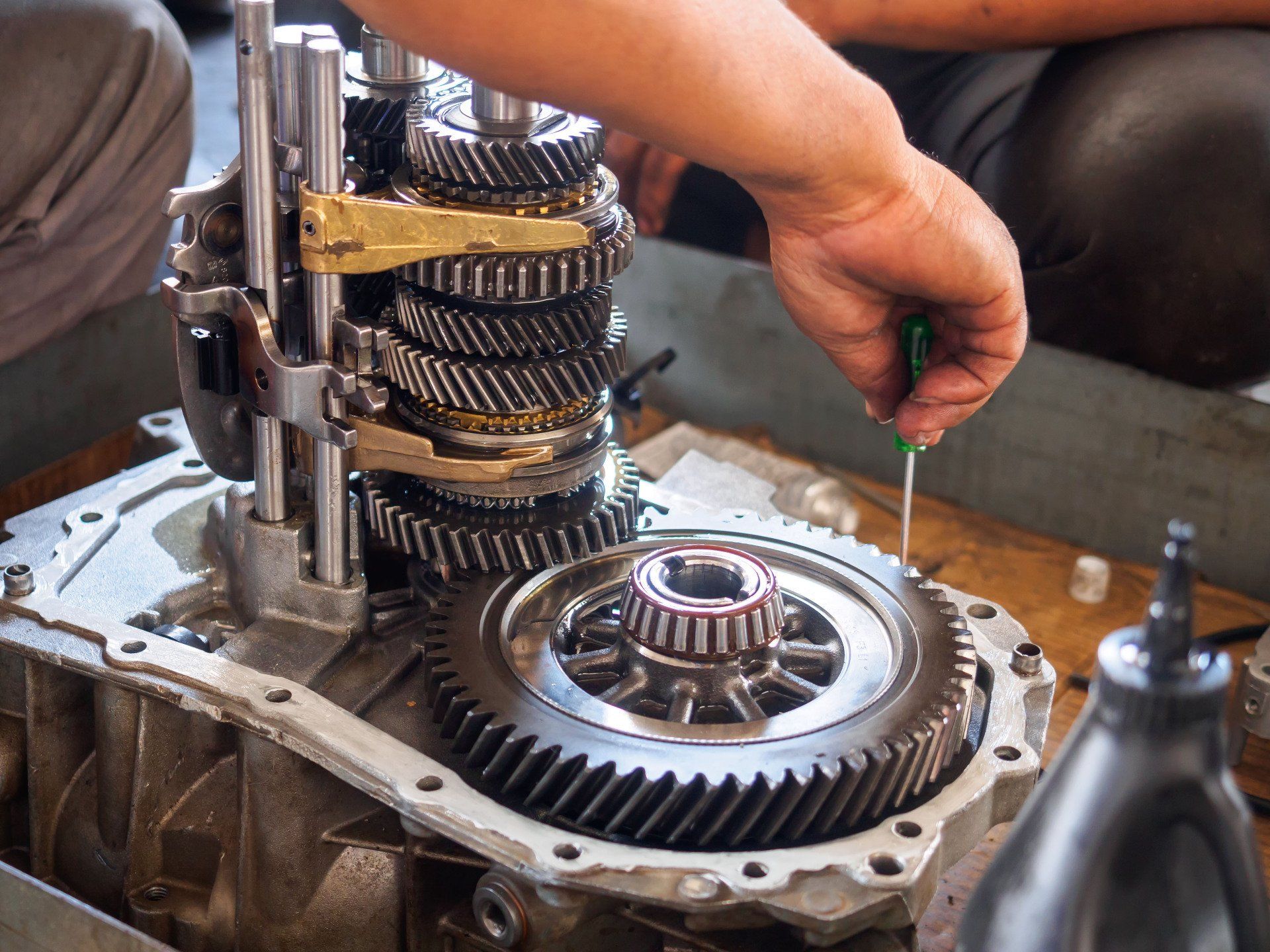

Did you know that, according to AutoWise, Isaac Babbitt created the first Babbitt metal in 1839? Clearly, this type of metal has been around for some time. A babbitt, which is a bearing coated in a tin alloy, is used a lot in industrial equipment and old engines. It's coated to reduce the rate at which the sensitive and otherwise softer part wears down. After being used for some time, a babbitt gets too large, so it needs to be replaced in order to maintain the original dimensions. This is the process that's called rebabbitting. Keep reading to learn more about this process and why it's important in several industries.

Applications of Babbitts

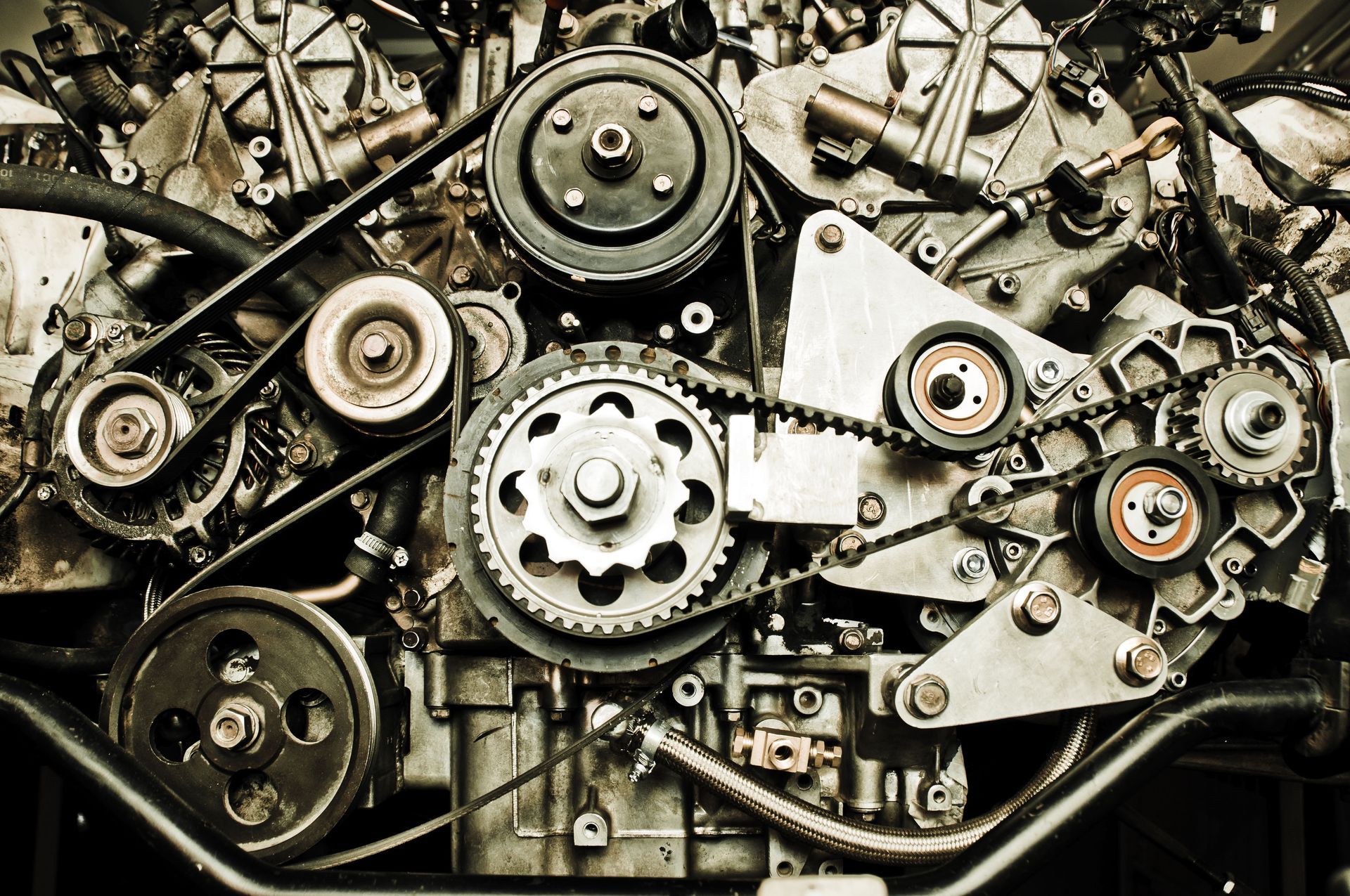

As mentioned, babbitts are used in industrial settings, and there are a number of applications for them. These include fluid film-lubricated and plain bearings for various industries. The automotive and marine industries are two of the industries in which babbitts are widely found. Whether it's in an internal combustion engine or an electric motor, large machinery, or small bearings, there are many applications that babbitting and rebabbitting can be used for.

Considerations

Investment castings, which are typically babbitted to extend their lifespan, are found in many settings and industries, as mentioned above. Babbitt metals are alloys of tin that are hardened with copper, antimony, and lead alloys that are sometimes hardened themselves with arsenic and another metal like antimony. The specific material to be used depends on the final application for which the babbitting or rebabbitting is to be put toward.

In order for rebabbitting to serve its intended purpose of protecting investment castings from rapid wear and tear, the workmanship must be perfect. Because these bearings are generally used in highly sensitive industrial applications, like oil, gas, and agriculture industries, they must be kept in good form throughout. Doing so can help tremendously in minimizing risks to people working around and with the machinery.

Are you interested in learning more about babbitting and rebabbitting? Call Effingham Regrinding Inc for any assistance that you need with rebabbitting, and we will give you the help you need. Based on the industry you work in, we can advise you on which products will work best in your field. We look forward to working with you!

Share On: